MISREGISTER

Mis-registration is one of the most common defects in flexo printing, caused by the separate colours of the print image, not being correctly positioned, resulting in a blurred image or variations in colour in tonal images

Cause

1 The printing plates are not mounted in register.

2 The web tension is not correct.

3 Wrong drive-roller setting.

4 Too high web temperature.

5 The compensation roller for the print register of the machine is not centred.

6 The idle rollers are dragging or rotate intermittently.

7 The press is out of alignment.

8 Incorrect damaged drive gear.

Solution

1 Remount the printing formes in register. Check forme mounting and forme mounting equipment. Check forme thickness. Check the relief height of the forme and if there is any distortion. Check mounting tape thickness.

2 Adjust web tension control in the relation to substrate used.

3 Check parallel of the web guide rollers to be sure that the pressure setting is uniform across the web width.

4 Reduce temperature in the dryers.

5 Centre the compensating roller of the side register and longitudinal register and then manually adjust print register.

6 Replace or lubricate the idle roller bearings.

7 Realign the press.

8 Replace drive gear.

Helmut Mathes, troubleshooting defects supplied curtesey of Flexo & Gravure Int''l 2011

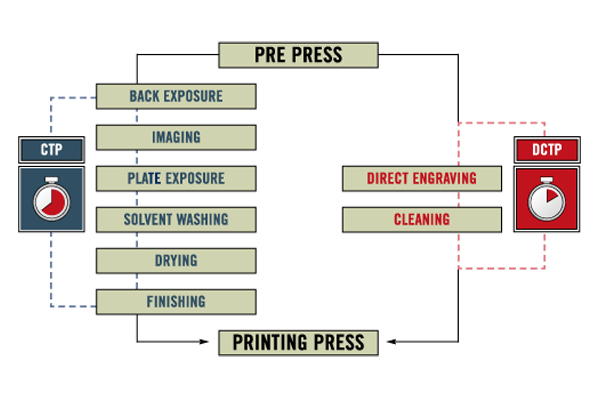

PRE-PRESS

Controlling the variables in the Pre-press of the flexo process, helps to eliminate variations and printing defects.

Read moreINK TRANSFER - FLEXO PRINT FORM

The flexo print form is a fundamental part of the printing process and has a significant impact on ink transfer and cleanliness of the inking process.

Read more